Overview of the REE4EU project

REE4EU’s technology to recover REEs from secondary sources involves two steps: ionic liquid extraction followed by high temperature electrolysis. The technology was validated and showcased through a pilot plant, integrated into an existing facility. Different waste feeds were used to carry out proof-of-concept at industrially relevant scale. First, permanent magnet swarf (PMS) was targeted. Then, the process was replicated with end-of-life permanent magnet (PM) and other end-of-life wastes from an existing battery recycling plant.

The output material from the REE4EU pilot process was validated by producing and characterising permanent magnets and assessing their quality in terms of magnetic properties, i.e., remanence, coercivity, intrinsic coercivity and maximum energy product, as well as chemical composition. The results showed that the permanent magnets prepared from the recycled material obtained by the REE4EU solution had the same properties as those manufactured using virgin material.

Thus, REE4EU demonstrated for the first time a closed-loop recycling scheme for permanent magnets in Europe. This leads to the conclusion that Europe should develop and implement the right market conditions for REE recovery, as well as enable best practices on end-of-life products’ management to maximise the recovery of REE, especially in the case of waste from electronic and electric equipment.

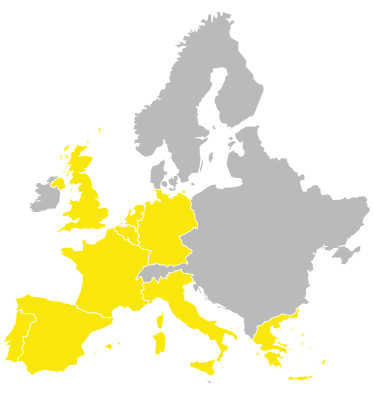

The REE4EU consortium comprised 14 partners from 8 European countries. The project started in October 2015 and continued until September 2019. Funding was received from the European Union’s Horizon 2020 Research and Innovation programme. On September 11th 2019, the consortium gathered to present to the European Commission’s project monitor the latest results and overall achievements.

Objectives of the project

- Provide Europe with a stable, circular value chain for REEs.

- Help European industries be more competitive and environmentally friendly by establishing a greener method of obtaining REEs.

Our involvement in the project

PNO had several responsibilities within the REE4EU project:

- Ensure and maximise the impact of the REE4EU project, paving the way for the market uptake of the proposed technology.

- Identify a relevant audience of stakeholders, policy makers, researchers and investors by performing a stakeholder and market analysis. These activities allowed us to build a targeted set of communication and dissemination

- Prepare a business plan, assessing the profitability of the envisioned REE4EU plant.