Overview of the Carbon4PUR project

Carbon4PUR was set up to develop and demonstrate (TRL4-6) a new flexible technology for the production of value-added chemicals, polyester polyols, of carbon derived from steel mill gas.

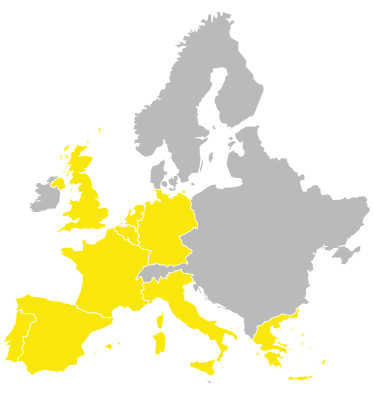

14 participants from 7 European countries constituted the project consortium: 4 industrial partners, 5 universities, 1 research organisation, 1 industry association, 2 service providers and the Grand Port Maritime de Marseille-Fos.

Carbon4PUR started in October 2017 and continued until March 2021. The Sustainable Plastics Symposium on March 25, 2021 was the great highlight of Carbon4PUR, concluding the project and presenting its major outcomes. With 412 registrants from 46 countries and almost 250 active participants there was a tremendously positive engagement. The high interest proves that current efforts towards a circular economy and the investigation of novel pathways utilising CO/CO2 as a feedstock is bearing fruits.

Funding for the project was provided by the European Union’s Horizon 2020 research and innovation programme (H2020-SPIRE-2017 call).

Objectives of the project

- Reduce carbon footprint of polyurethane intermediates compared to today’s polyurethane products manufactured from crude oil due to the re-utilisation of anthropogenic CO and CO2.

- Provide – first time from waste CO – higher value novel polyols for the production of new, sustainable polyurethane applications (rigid foam and coatings) as an example of high value polymers, matching market needs and requirements.

- Implement a direct conversion of carbon from the steel mill gas mixture to building blocks for the production of polyol intermediates.

- Condition industrial steel mill gas by avoiding expensive ‘traditional’ purification and conditioning methods.

- Prepare Industrial Symbiosis between consortium partners in the Grand Port Maritime de Marseille-Fos (France).

- Demonstrate the economic and social feasibility of the new technology.

- Exploit and transfer project results to key stakeholders and additional EU industries.

Our involvement in the project

PNO Chemistry contributed with a focus to realise a value chain and stakeholder analysis to identify the most important stakeholders of Carbon4PUR technology along the value chain and assess their position towards the project’s results. We were also responsible for setting up the exploitation plan.