Overview of the DEMETER project

Genencor International, part of the DuPont Industrial Biosciences Group, had developed a new enzyme product, derived from Myceliophthora thermophila C1. In a number of field trials this enzyme had already shown a promising 10% cost reduction in the production of biogas from organic waste. Although the efficacy of the enzyme was obvious, the fermentation process did not provide sufficient yield in industrial production to be cost-effective for large-scale application.

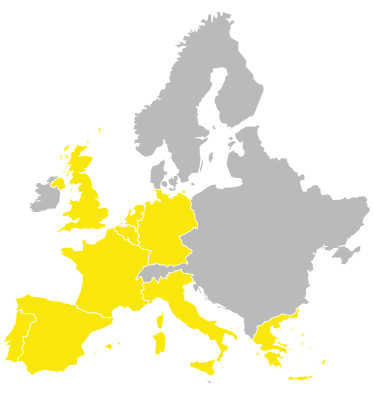

The DEMETER project increased the yield of this industrial fermentation process by 20%, improved the product recovery process by 40%, and reduced overall product cost by 15% while increasing the productivity of the process. In addition, DEMETER demonstrated the efficacy of the C1 enzyme in 8 field trials in biogas plants throughout Europe.

The DEMETER consortium included the entire value chain: Genencor International (enzyme producer), Miavit (enzyme retailer), BioBase Europe Pilot Plant (pilot plant), OWS (anaerobic digester expert), DBFZ (independent research centre with a focus on the efficient use of biomass), Biomoer (field trials) and PNO Ciaotech (independent economic and environmental evaluation).

DEMETER brought innovation to both the fermentation process used for production of the C1 enzyme, and to the use of enzyme-enhanced fermentation in the production of biogas. The project ran from 2016 to 2020. Funding was provided by the Bio-Based Industries Joint Undertaking (BBI JU) programme, part of Horizon 2020.

Objectives of the project

- Increase the yield of the fermentation process used for the C1 enzyme production at an industrial scale.

- Reduce the cost of the end product.

- Make the C1 enzyme available for wide-spread application in biogas production throughout Europe.

Our involvement in the project

PNO Ciaotech played an important role within the project as a pivot in dissemination and communication, took care of the techno-economical evaluation of the project and developed the exploitation plan. During the project, project coordinator Genencor was assisted by PNO’s chemistry and process consultants. Their tasks included project management, periodic and final reporting, chairing consortium meetings and coordinating communication with the project officer.